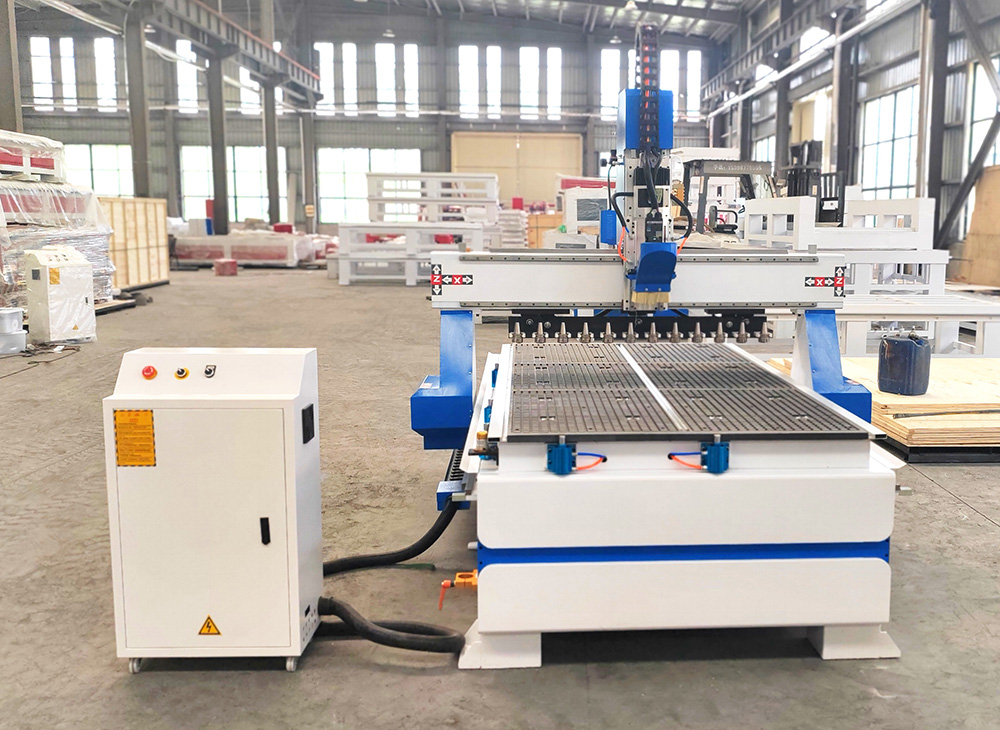

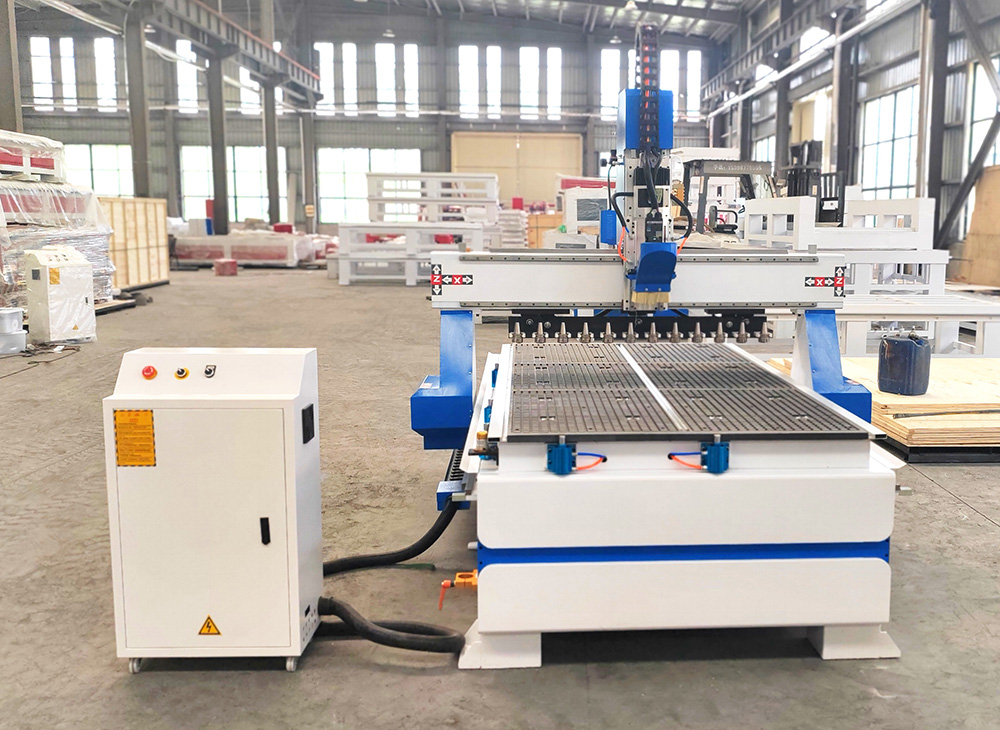

Woodworking ATC CNC Router Machine

The main functions and features of the automatic tool changing Woodworking ATC CNC Router Machine

Automatic tool changing system: the wood cnc router machine with compatible tool magazine with multiple tool positions.

High precision machining: Using an integrated industrial computer control system to ensure high-speed and high-precision machining of the machine tool, meeting the needs of precision machining.

Multi functional processing: suitable for processing non-metallic materials such as density boards, cabinet doors, computer desks, panel furniture, as well as carving and processing non-ferrous metals such as copper and aluminum.

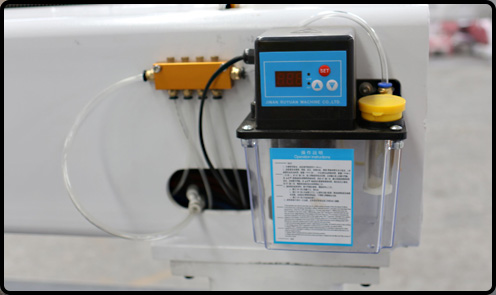

High efficiency design: The machine body is constructed from thick walled steel pipes, and after finite element analysis and design.it provides a rigid and stable machining platform. All positioning bearings, ball screws, linear guides, and racks are maintained by the centralized automatic lubrication system of the machine control system to ensure that the machine runs at high speed for a long time without deformation or shaking.

High power spindle: Equipped with a high-power spindle motor, capable of carving various materials.

Six zone vacuum adsorption table: It can effectively adsorb plates of different sizes, improving processing efficiency.

Environmental design: Adopting high-power dust removal device to improve working environment and extend machine service life.

Compatible with multiple software: compatible with various CAD/CAM software such as Type3/Artcam/Castmate/Pro/UG/Wentai, to achieve diverse design and processing needs.

Product Parameters

| Description | Parameter |

| XYZ working area | 1300*2500*300mm/1500*3000*300mm/2100*3000*300mm/2100*4000*300mm |

| XYZ travel positioning accuracy | ±0.03/300mm |

| XYZ repositioning positioning accury | ±0.02mm |

| Table surface | Vacuum table |

| Gantry | Heavy steel welded structure |

| Drive system X-Y axis | Rack actuation |

| Drive system Z axis | Ballscrew |

| Spindle power | 9 KW learning atc air cooled spindle |

| Max velocity | 0-60000mm/min |

| Max working speed | 0-25000mm/min |

| Spindle speed | 0-24000rmp |

| Work mode | Hybrid servo motor |

| Working voltage | AC220V or 380V |

| Operating system | LNC/Weihong/Mach3 /Syntec System |

| X-Y resolution | <0.02mm |

| Gross weight | 1600kg |

Detailed Photos

The Woodworking ATC CNC Router Machine with automatic tool change system, and 12 tools, and can choose from 10 tools, 8 tools, 6 tools, etc.

The well-known 9 Kw JST ,HQD or HSD ATC air-cooled spindle has strong cutting ability, low noise, and long working time.

This CNC engraving machine is equipped with Mach3 control system, Yako hybrid servo motor, Taiwanese HIWIN guide rail, spiral rack, etc.

Suitable for panel furniture, solid wood furniture, office furniture, wooden door products, and other non-metallic and soft metal applications.

|

|

|

|

|

|

|

High strength bed structure |

9KW learning Air-cooled tool changing spindle |

Yako hybrid servo motor |

|

|

|

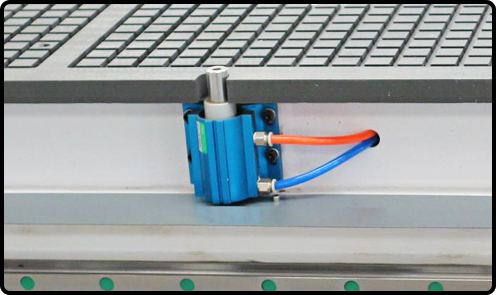

| Prevent static electricity drag chain | Position cylinder | Six zone vacuum table |

|

|

|

| HIWIN Helical guide rail | Automatic lubrication | Dust collector |

Optional Accessories :

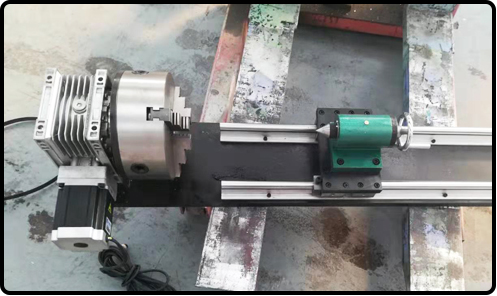

Rotary axis:The rotary axis is mainly used for 3D carving, such as Roman columns, art statues, decorations, etc

Servo Motor:If you have high precision requirements, you can choose servo motor. Yako or Syntec Servo motor have higher precision and performance

Many accessories in our cnc wood router machine can be customized and be changed. The system offers options such as Ncstudio system, LNC, Syntec system, and Mach3. Spindles available for selection include HQD and HSD. You can customize according to the materials and requirements you want to process.

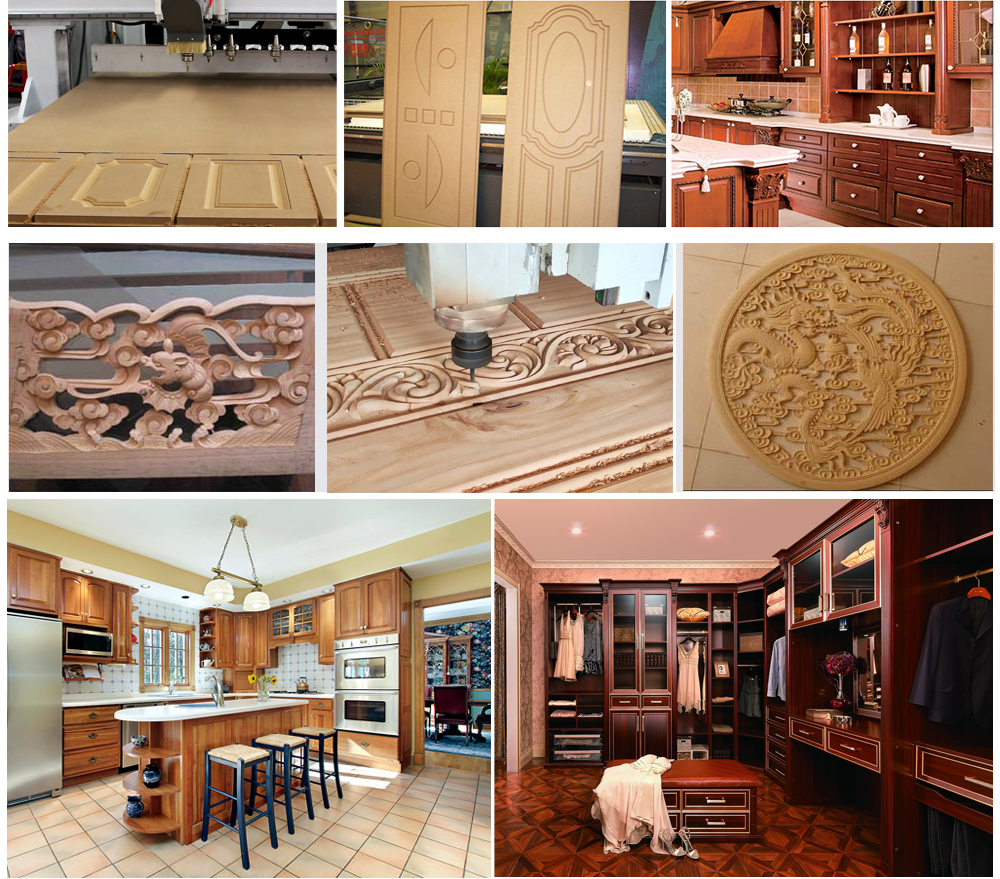

Working Samples

The Woodworking ATC CNC Router Machine is mainly used in the wood industry, advertising sign production, furniture manufacturing, toy and gift manufacturing, decoration industry, and PCB production

After service

1. Online after-sales consultation: inquire about the use, maintenance, and upkeep of the product.

2. Online after-sales technical support: Provide technical support related to product usage.

3. Online after-sales maintenance guidance: Provide customers with after-sales maintenance services for products, including replacement of spare parts, repairs, etc.

4. Online training: Provide customers with training on the use of the product, enabling them to better understand its features

Characteristics and usage methods.

5. After sales complaint handling: Provide customers with a complaint handling mechanism, timely understand and handle customer complaints, and ensure

Verify customer satisfaction.