large bed cnc router

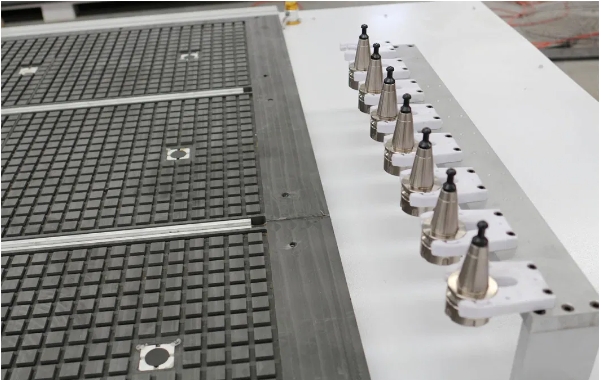

The large bed cnc router machine is equipped with automatic tool change system, equipped with 8 tools, and can choose from 12 tools, 10 tools, 6 tools, etc.

The well-known 5.5 Kw JST or HQD ATC water-cooled spindle has strong cutting ability, low noise, and long working time.

This large bed cnc router machine is equipped with LNC or Weihong control system, Yako servo motor, Taiwanese HIWIN guide rail, spiral rack, etc.

Suitable for panel furniture, solid wood furniture, office furniture, wooden door products, and other non-metallic and soft metal applications.

Product Parameters

| Name | Large cnc router machine |

| Table Surface | Vacuum Table |

| Xyz Working Area | 2100*3000*300/2000*3000*300/2100*4000*300mm |

| Positioning Accuracy (mm) | 0.03/200mm |

| Repeatability (X/Y/Z) (mm) | 0.02 |

| Spindle Speed | 0-24000rmp |

| Max.Speed | 0-60000mm/Min |

| Max.Working Speed | 0-25000mm/Min |

| Working Voltage | AC220V or 380V |

| Drive Type | AC Servo Drive |

| Usage | Woodworking, Metal, Plastic, Stone, Rubber, Advertising, Mould |

| Operating System | Taiwan Lnc/Weihong System |

| Weight (Kg) | 1500 |

Detail photos

|

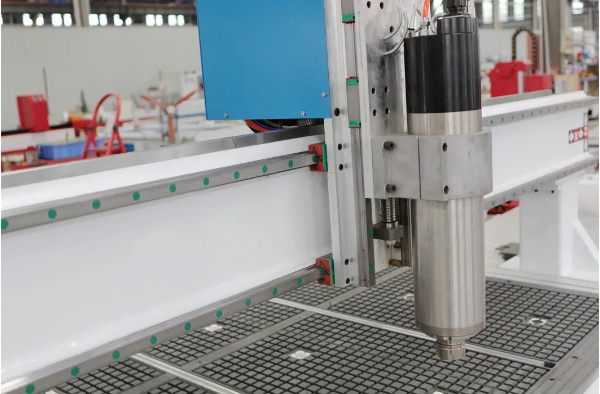

The 5.5KW water cooled spindle (optional air cooled spindle )with ATC The water-cooled spindle operates smoothly and is easy to start |

|

Linear automatic tool changing system The atc changing tools system with 8 knives.Faster processing speed, saving time |

|

Yako or Leadshine servo motor The Servo motor have higher machining accuracy and longer lifespan |

|

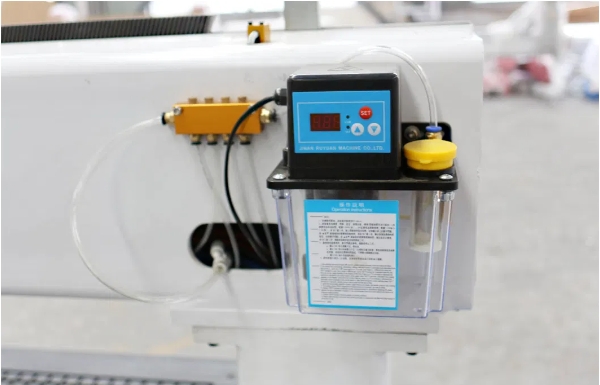

Automatic oilerAutomatic oiler eliminates manual operation and simplifies maintenance |

|

Vacuum tableThe vacuum adsorption countertop can better secure the materials.

|

Working Samples

large bed cnc router machine are suitable for carving and processing non-metallic materials such as density boards, cabinet doors, computer desks, panel furniture, PVC, plastics, and non-ferrous metals such as copper and aluminum