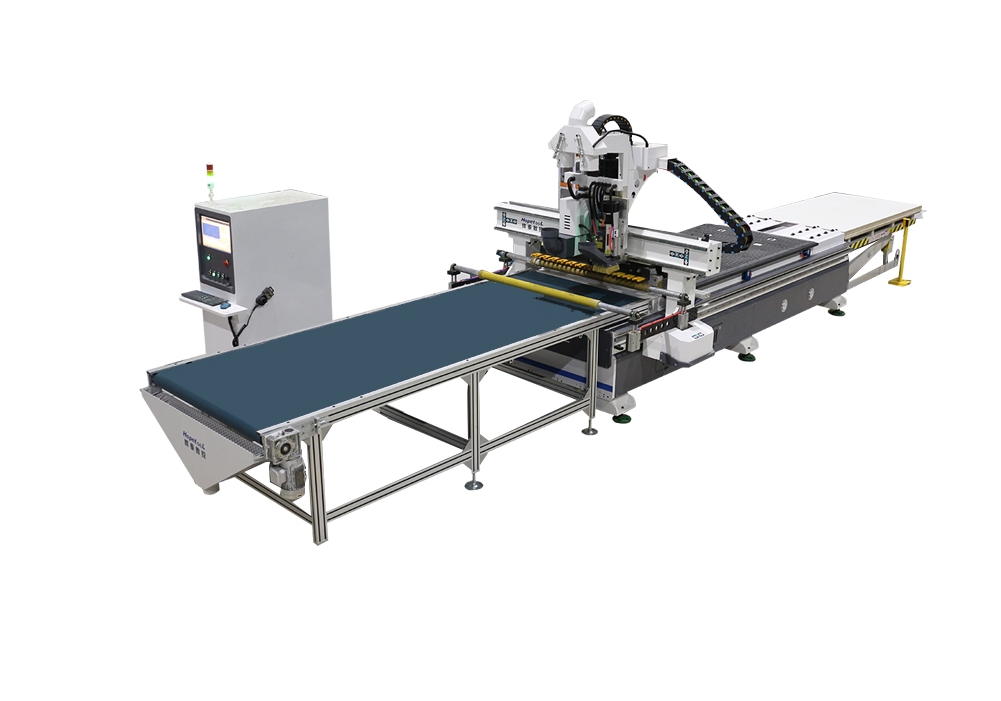

Auto Loading Unloading Cnc Router

Characteristic:

1)Auto Loading Unloading Cnc Router is linear Auto tool change machine,and with uploading and downloading table,with high efficiency.

2)Adopt Yako servo motor ,built-in encoder,It can stop automatically when graunch happens,so can avoid accidents .

3)JST or HQD air cooling spindle or China air cooling spindle with tool change, high power , imported tool holders with high

precision and long lifetime.

4)Whole machine is welded with seamless steel structure, the regidity is good , not easy to be deformed.The gantries adopt steel

structure

5)Taiwan LNC leading control system,Advancedfile pretreatment function can correct the error in the files and is compatible with the process codes of multiple national andinternational software. (such as Mastercam,Typ3,UG,Artcam,Caxa).

6)6 zones vaccum table, it is a professional wood door making and furniture making machine.

|

Description

|

parameter

|

||

|

XYZ working area

|

1300*2500*200mm

|

1500*3000*200mm

|

2000*3000*200mm

|

|

Table size

|

1440X3040mm

|

1640*3540mm

|

2140*3540mm

|

|

X,Y,Z Traveling Positioning Accuracy

|

±0.03/300mm

|

||

|

X,Y,Z Repositioning Positioning Accuracy

|

±0.025mm

|

||

|

Lathe Structure

|

Welded Strucutre

|

||

|

X, Y Structure

|

Gear Wheel Transmission, Shaft Linear Bearings

|

||

|

Z Structure

|

Ball Screw, Shaft Linear Bearings

|

||

|

Max.Consume Power

|

20KW

|

||

|

Max.Speed

|

0-60000mm/min

|

||

|

Max.Working Speed

|

0-25000mm/min

|

||

|

Spindle Power Motor

|

9KW ATC spindle

|

||

|

Spindle Speed

|

0-24000RPM

|

||

|

Working Mode

|

Servo system

|

||

|

Working Voltage

|

AC380V/50/60Hz , 3PH

|

||

|

Command

|

G Code, *uoo, *mmg, *plt

|

||

|

Operating System

|

SYNTEC or Weihong System

|

||

|

Interface

|

Internet line

|

||

|

Flash Memory

|

512M

|

||

|

Collet

|

ER32

|

||

|

X,Y Working Delicacy

|

<0.01mm

|

||

|

Software

|

Type3 software, Wentai software,Artcam software

|

||

|

Running circumstance

|

Temperature: 0°C~45°C,

Relative humidity: 30%~75%

|

||

|

Packing Size

|

4000x2150x2200 mm

|

||

|

Net Weight

|

2000KG

|

||

|

Gross Weight

|

2300KG

|

||

Product detail

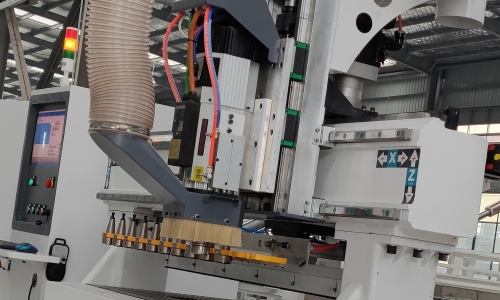

Automatic tool changing system

Auto Loading Unloading Cnc Router with 12 tool positions and tool libraries, controlled by a CNC system for quick tool changes and adaptation to different machining needs

|

|

| 9kw air cooling spindle | Japan brand reducer NIDEC |

|

|

| Taiwan LNC Control System | Pushing cylinder |

|

|

| 4 pcs positioning cylinders at Y direction | Auxiliary feeding wheel |

|

|

| Automatic timing oil filling-system | Taiwan high quality guide and rack |

|

|

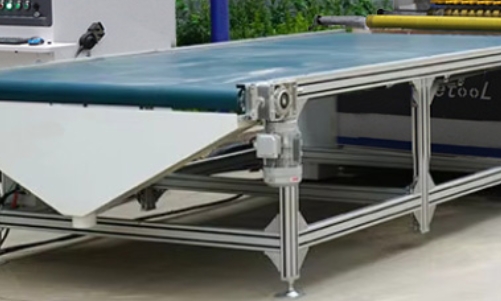

| Auto loading table | Auto unloading table |

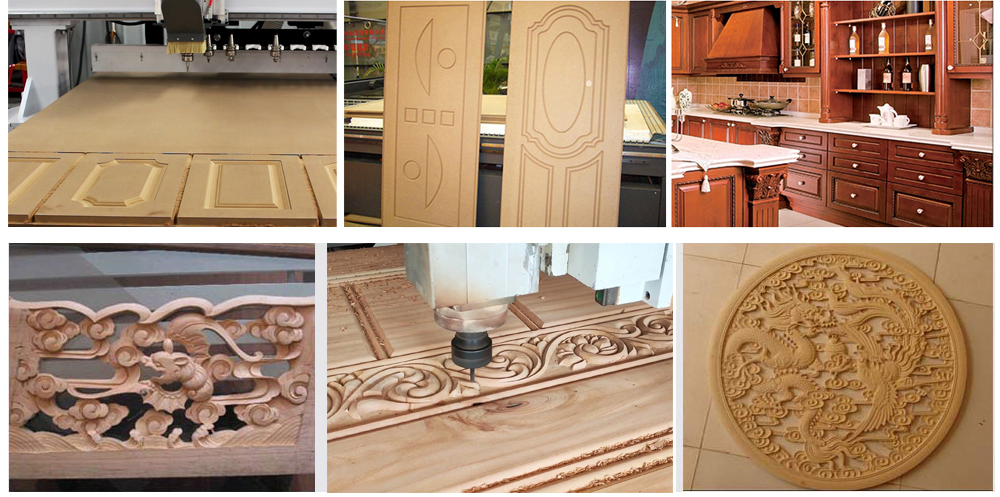

Application

The Auto Loading Unloading Cnc Router machine are very wide, mainly including woodworking industry, advertising industry, mold industry, etc

Furniture: wooden doors, cabinets, boards, offices and wooden furniture, tables, chairs, doors and windows, etc

Advertising industry: producing advertising signs, logo production, acrylic cutting, molding system modules, etc

About us

Jinan Hopetool CNC equipment Co.ltd. is a professional company specializing in developing and manufacturing CNC router , co2 laser machine,fiber laser cutting machine ,digital cutting machine.After 15 years’ hard work, our machines have been exported to more than 80 countries, and we have established regular business relationships with many distributors from many countries.

FAQ:

Q1.How to get the most suitable machine and best price?

Please tell the material you want to working on ? How to working on it ? Engraving ? Cutting ? Or other ? What’s the MAX size of these material ?( length ? Width ? Thickness ?)

Q2.What is the payment?

The payment is 30% or 50% T/T or Alibaba trade assurance in advance, balance after machine finished.

Q3.What is the producing time after order?

The proucing time is about 10-20 days depend on different machines.

Q4.If we don’t know how to use the machine,can you teach us?

Yes,we will ,if you come to China,we will offer you free training until you can use machine freely.And if you are busy ,we will have the special engineer to your country,but you need to bear some fee,like tickets and hotel and meal.

Q5.How about your after-sales service?

we offer you 24 hours service phone,skype or whatsapp, our engineer also can go to door install or training.

Q6. Quality Control:

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure they can work very well before being out of factory. The testing video and pictures will be available before delivery.