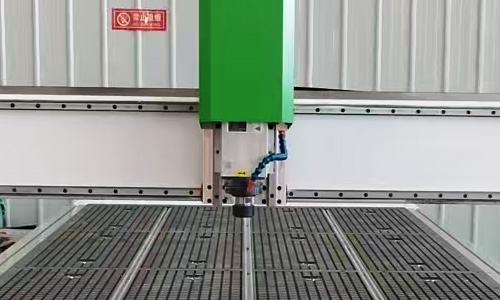

4X8 3d cnc router machine

1、4X8 3d cnc router machine use a 4.5KW air-cooled spindle with great power.

2、The vacuum adsorption workbench with zone control can easily fix materials of different sizes and shapes.

3、Weihong control system, a commonly used system for engraving machines, is easy to operate and compatible with many software.

4、The X-Y axis uses gear rack transmission and Taiwan’s high-quality guide rails, making the machine durable.

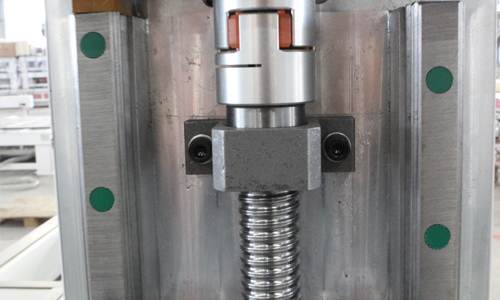

5、The Z axis uses TBI high-quality ball screw transmission with high repeatability.

Main accessories

|

|

| Vacuum table

Regional control, easy to fix different materials |

Air cooled spindle

4.5KW high-power spindle, great power |

|

|

| Taiwan rack

Taiwan’s high-quality guide rails, gear rack drive, the machine is more stable, |

TBI ball screw

The Z axis uses Taiwan’s TBI ball screw drive with high precision |

|

|

| Hybrid servo motor

Higher processing accuracy and speed than stepper motors |

Yako driver

Stable operation and good heat dissipation |

|

|

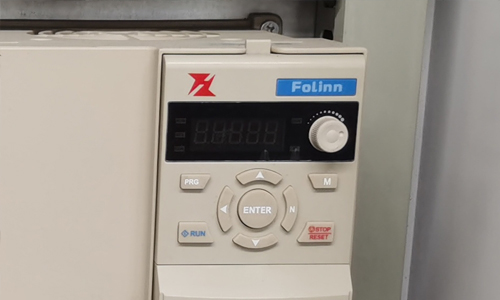

| Fuling inverter

Control the spindle speed according to processing requirements |

Weihong control system

Computer interface, compatible with many software, simple operation |

|

|

| Limit switch

Control the spindle stroke, safer during production |

Tool sensor

Detect the status of the tool and improve the processing quality |

Main accessories maintenance

1. Clean the dust and debris on the surface of the motor frequently to ensure normal heat dissipation of the spindle and prevent the spindle from overheating and damage.

2. Clean the dust and debris of the guide rails, screws, racks, and gears after work every day, and apply lubricating oil regularly.

3. Clean the 4X8 3d cnc router machine work table and surrounding debris and sundries after work every day to ensure production safety

4. Check the oil level of the lubricator and whether the lubrication pipeline is unobstructed.

Product parameters

| Work area Width/Length | 1300 mm x 2500 mm |

| Z Travel | 200mm |

| Processing material thickness | 200mm |

| Table | Vacuum Table with T-Slot |

| Voltage | 220V Single phase optional 380V,three phase |

| Operating System | Weihong system |

| Inputs | USB |

| Spindle Power | 4.5KW |

| Cooling method | Air cooled |

| Max Speed | 24000rpm |

| Motor | Yako Hybrid servo motor |

| Max Cutting Speed | 50m/min |

| Repositioning | 0.025MM |

| Machine Footprint | 3100mm x 2250mm x 1850mm |

| Electrical Cabinet Size | 3000mm x 2050mm x 1750mm |

| Net Weight | 1200 kg |

| Gross Weight | 1300kg |

Optional part of 4X8 3d cnc router machine

1. Rotating axis, cylindrical or other special-shaped material engraving

2. Replace with water-cooled spindle, which can be used for metal and stone engraving

3. Replace with automatic tool change spindle, which automatically changes the tool to improve work efficiency

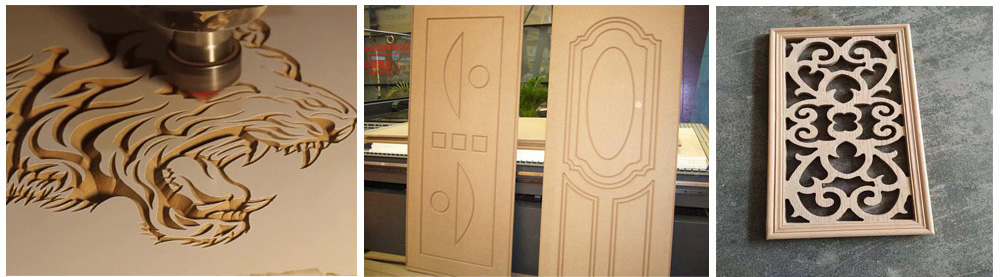

Application

Processing materials 4X8 3d cnc router machine: density board, solid wood board, synthetic board, multi-layer board, planed board, PVC, gypsum, two-color board, aluminum-plastic board, hibiscus board, plexiglass, acrylic, ABS, horn, various hard plastics, etc.

1. Furniture industry: cabinets, doors, beds, tables, chairs, counters, etc.

2. Musical instrument industry: such as piano, guitar, violin, etc.

3. Advertising industry: advertising signs, logo production, acrylic cutting, etc.

4. Craft gift industry: 3D engraving, relief and other craft gifts

Our factory

Our factory has 15 years of production experience,and producing and selling woodworking cnc rotuer machines, metal and stone engrave machines, laser cutting machines, flatbed cutting machines, etc.

The products use high-quality accessories, the quality of the machines is good, and there are many certificates (FDA, CE, ISO, etc.).

We are factory direct sales, with cheap prices. And our machines have been sold to more than 80 countries around the world, and we have long-term partners in many countries.

Welcome dealers from all countries to visit our factory!