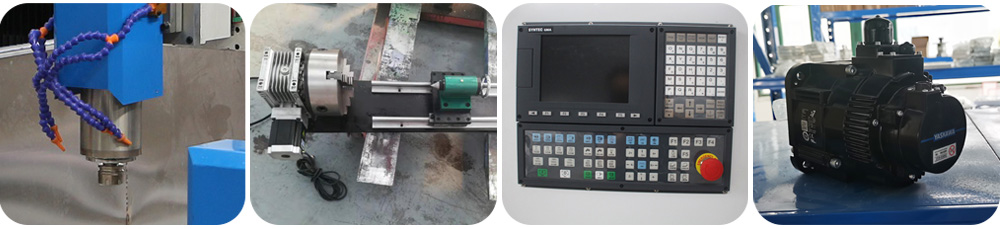

2000×3000 automatic tool changer cnc router

working area 2000x3000mm.

servo motor and driver.

9KW spindle with ATC tool changer.

LNC control system.

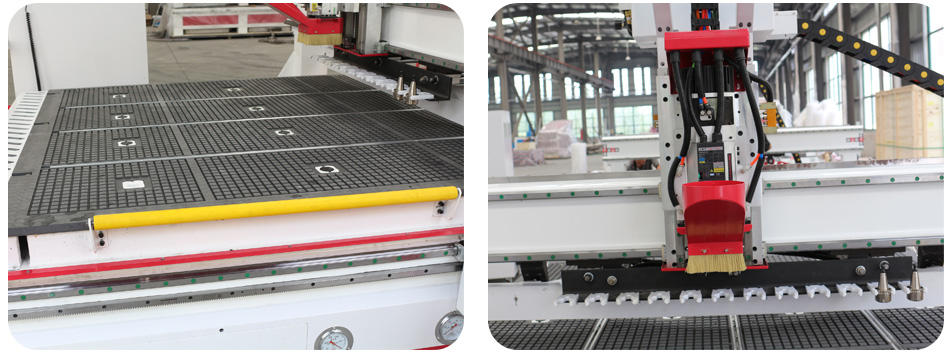

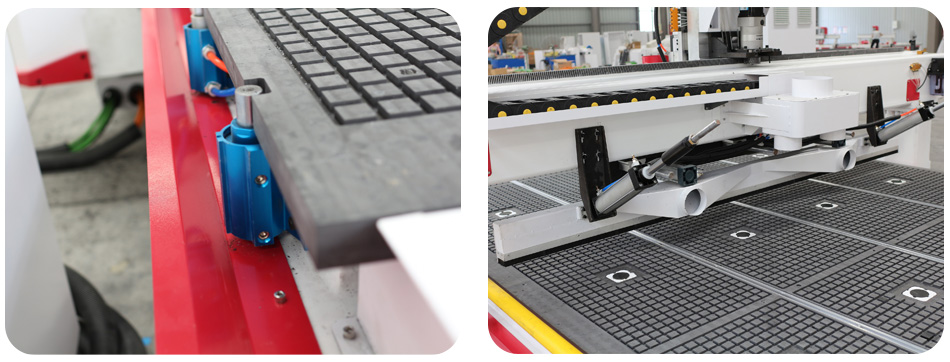

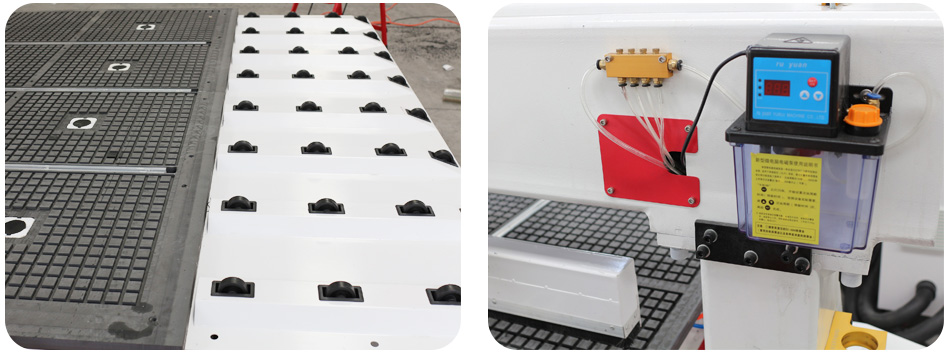

vacuum table.

Product Introduction

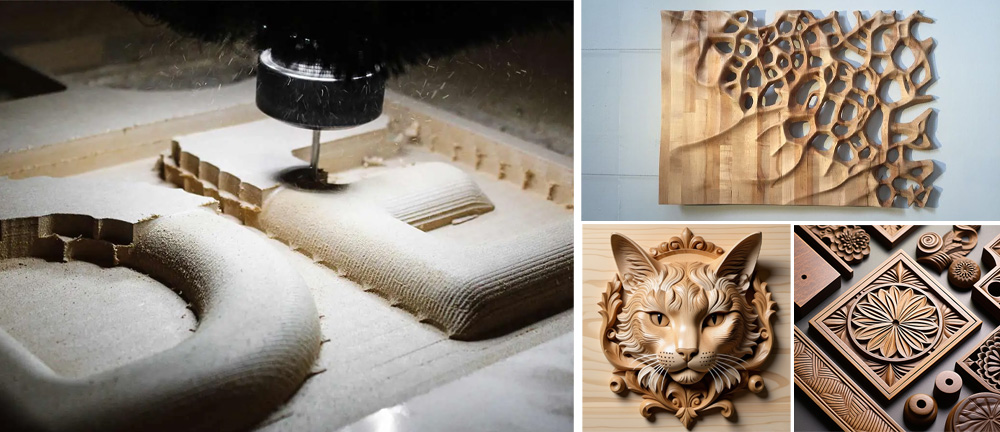

The 2000×3000 automatic tool changer cnc router is used for furniture manufacturing, and can also be used in woodworking, advertising logos, plastic processing and other industries. The machine automatic tool change function can working continuously and quickly, which can improve production efficiency.

Main Features

1. Working area 2000mm×3000mm (X×Y axis), Z axis travel 300mm (can be increased).

2. Square tube welded frame structure, strong and durable.

3. Linear tool magazine, 12 tools automatically switched.

4. 2000×3000 automatic tool changer cnc router with 9KW air-cooled spindle, speed 0- 24000 rpm.

5. Servo motor,NIDEC reducer, ensure high precision and high speed.

6. Taiwan LNC control system, support G code programming, compatible with a variety of design software (such as Type3, Artcam, Castmate, Proe/UG, etc.).

Technical Parameters

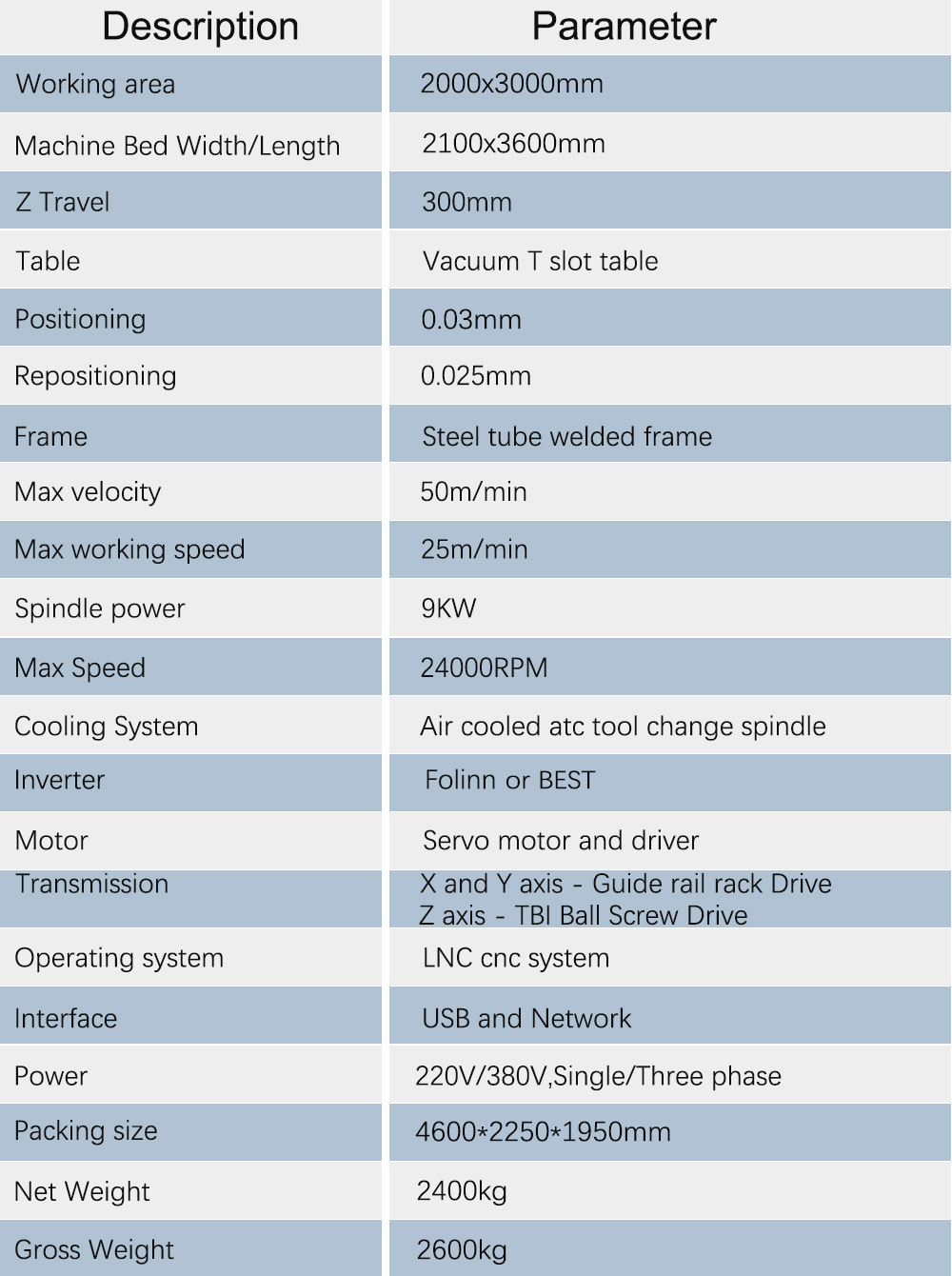

Optional accessories

High-power water-cooled spindle: water circulation cooling spindle, fast cooling speed, low noise.

Rotary axis: can rotate engraving, engraving angle and length can be set, such as Roman columns.

SYNTEC control system: Taiwan control system, the system works stably and is updated regularly.

Yaskawa servo motor: stable performance and long life.

Product images

Application

2000×3000 automatic tool changer cnc router processing materials:wood, plywood, MDF, solid wood board, PVC, gypsum, aluminum-plastic board, acrylic, horn, hard plastic, etc.

Industry

1. Furniture industry: various furniture, cabinets, doors, beds, tables, chairs, counters, etc.

2. Musical instrument industry: such as piano, guitar, violin, etc.

3. Advertising industry: advertising signs, logo production, acrylic cutting, blister molding and other materials

4. Craft gifts industry: 3D carving, relief and other craft gifts

Our Company