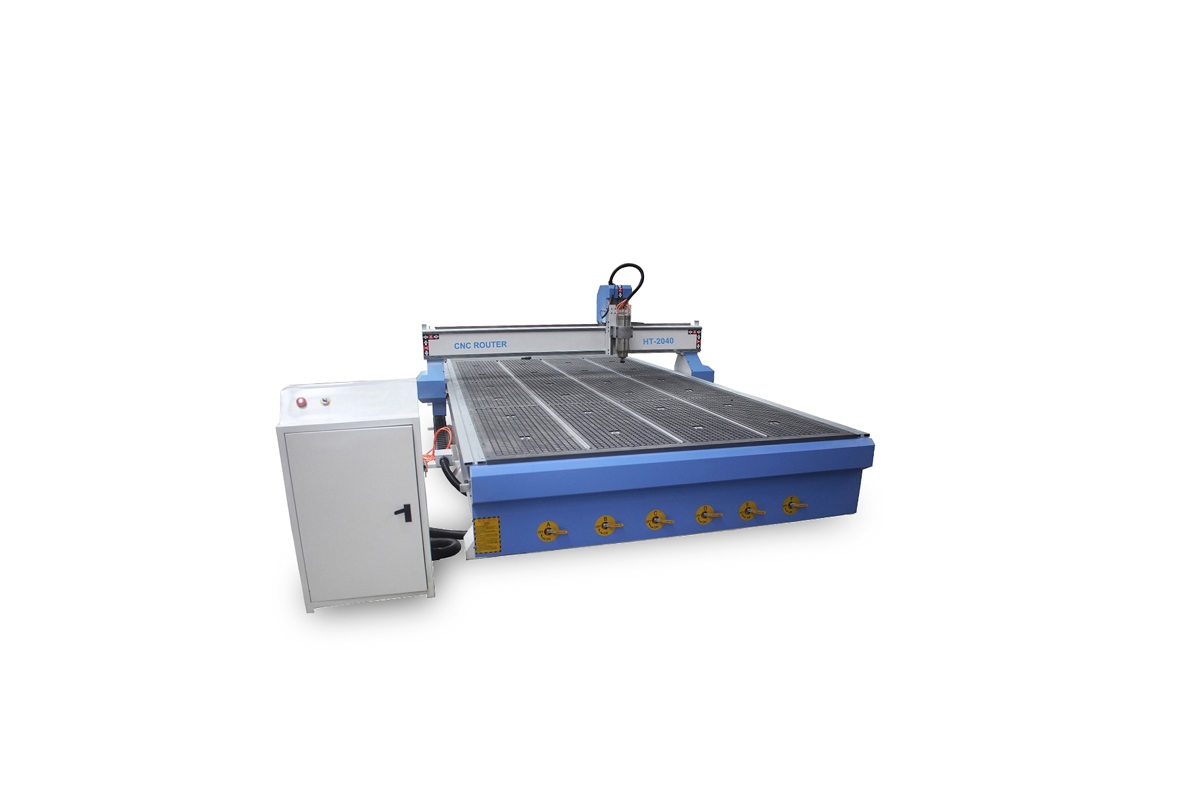

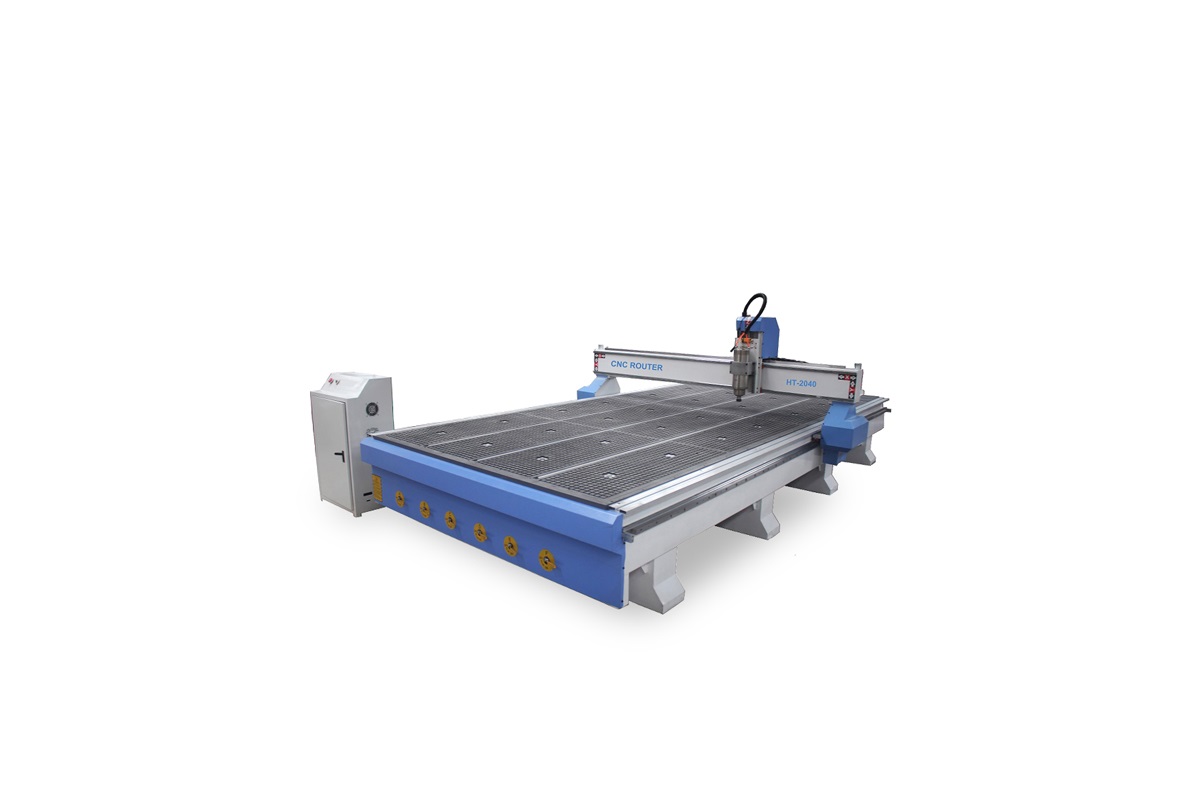

Woodworking CNC router 2040

Characteristic:

1.Water cooling spindle,high precision,long life time,steady working,easy to start up.

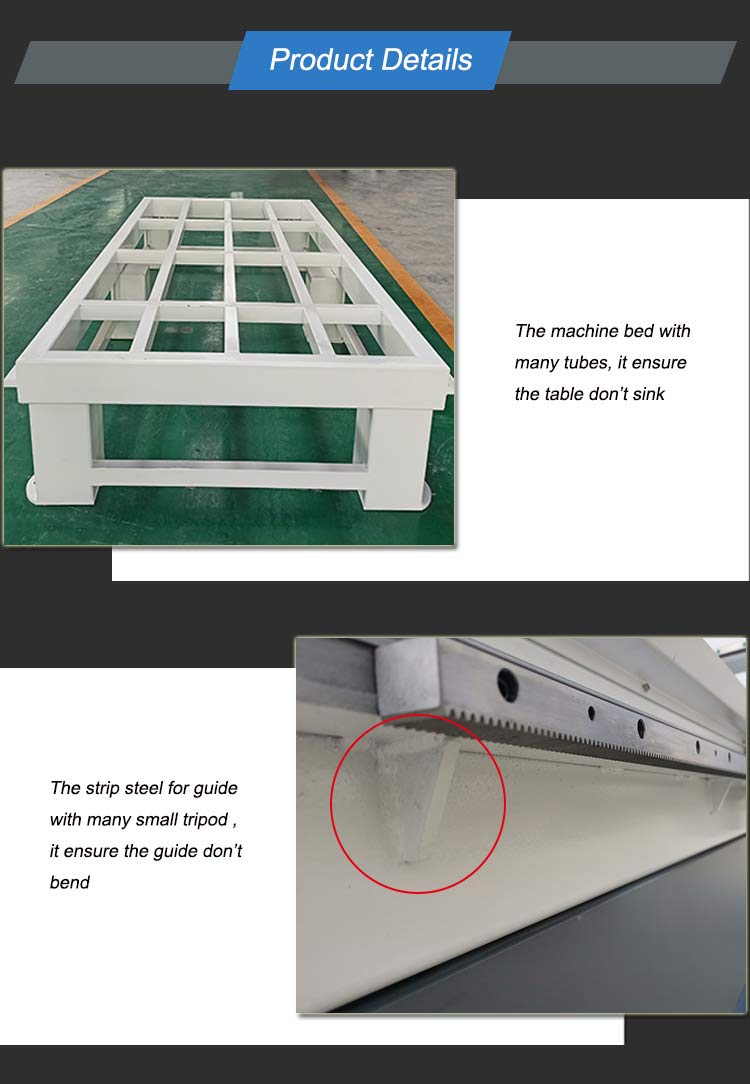

2.thicken square pipe stucture ,well welded, no distortion for whole structure high precision ,and long life time.

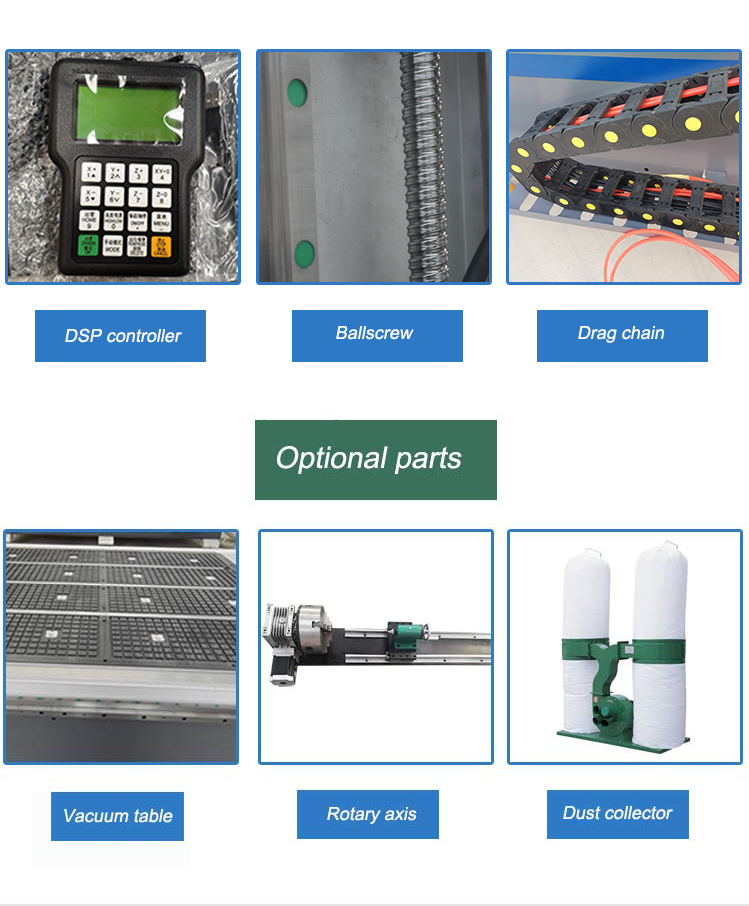

3.DSP controller system with USB interface,working without connecting with computer during working and easy to control.

4.Software:CAD/CAM designing software such as type3/artcam/castmate/weitai etc.

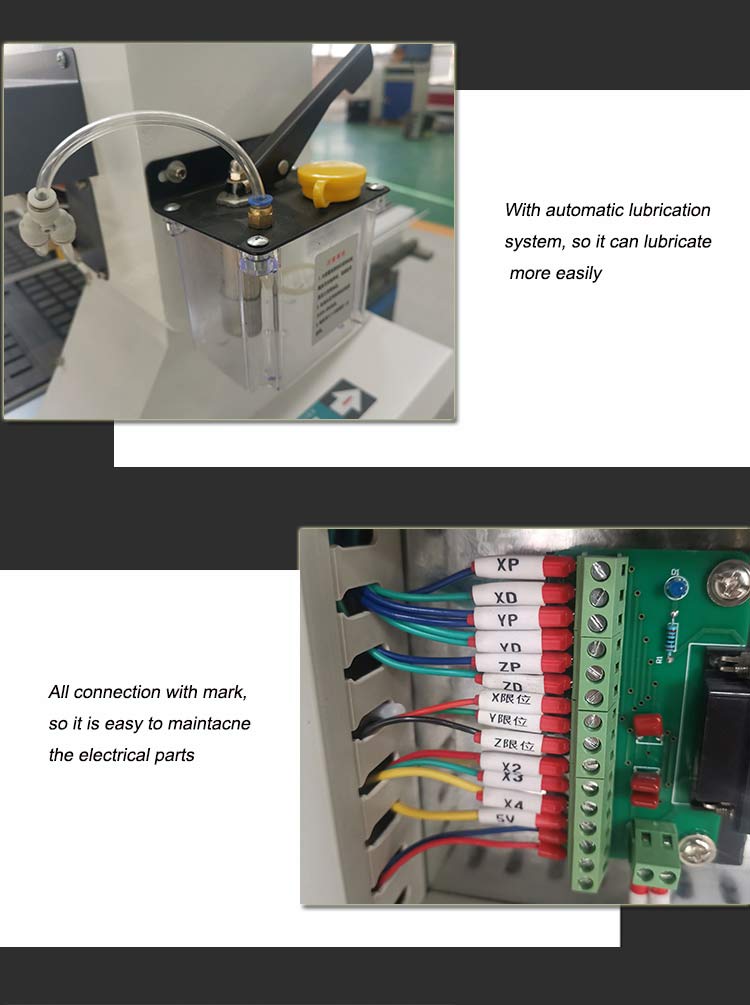

5.auto oilling system ,easy to operate by pressing one key.

6.seperated control system makes operation easily.

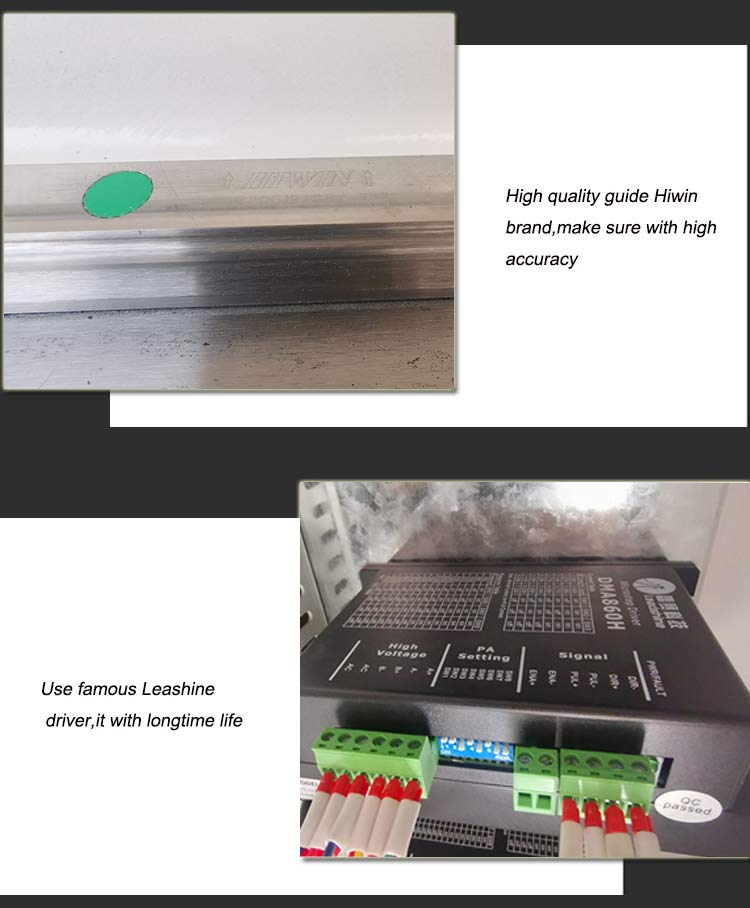

7.Adopt high speed stepper motor and drivers,and two motors for Y axis.max speed is 25mm/min.

8.The vacuum table holds tightly the carving materials which makes operating more reliable and convenient.

performance parameter

| number | Description | parameter |

| 1 | XYZ working area | 2000*4000*200mm |

| 2 | Table size | 2180*4500mm |

| 3 | XYZ travel positioning accuracy | ±0.025mm |

| 4 | XYZ repositioning positioning accury | ±0.025mm |

| 5 | Table surface | Bakelite vacuum table combiated T slot |

| 6 | frame | Steel |

| 7 | drive system X-Y axis | Rack actuation |

| 8 | drive system Z axis | Ball screw |

| 9 | Spindle power | 3/5.5KW spindle |

| 10 | Max velocity | 50m/min |

| 11 | Max working speed | 25m/min |

| 12 | Spindle speed | 0-24000rmp |

| 13 | work mode | Stepper |

| 14 | Working voltage | AC220V/380V |

| 15 | Command language | G code |

| 16 | Interface | USB |

| 17 | Operating system | DSP/Mach3/Ncstudio |

| 18 | Flash memory | 128 |

| 19 | X-Y resolution | < 0.025mm |

| 20 | Software environment | Ucancam type3 artcam |

| 21 | Running environment | Temperature:0-45°C |

| 22 | Paking size | 4800*2200*1800mm |

| 23 | Net weight | 2300kg |

| 24 | Gross weight | 2500kg |

Machine Parts:

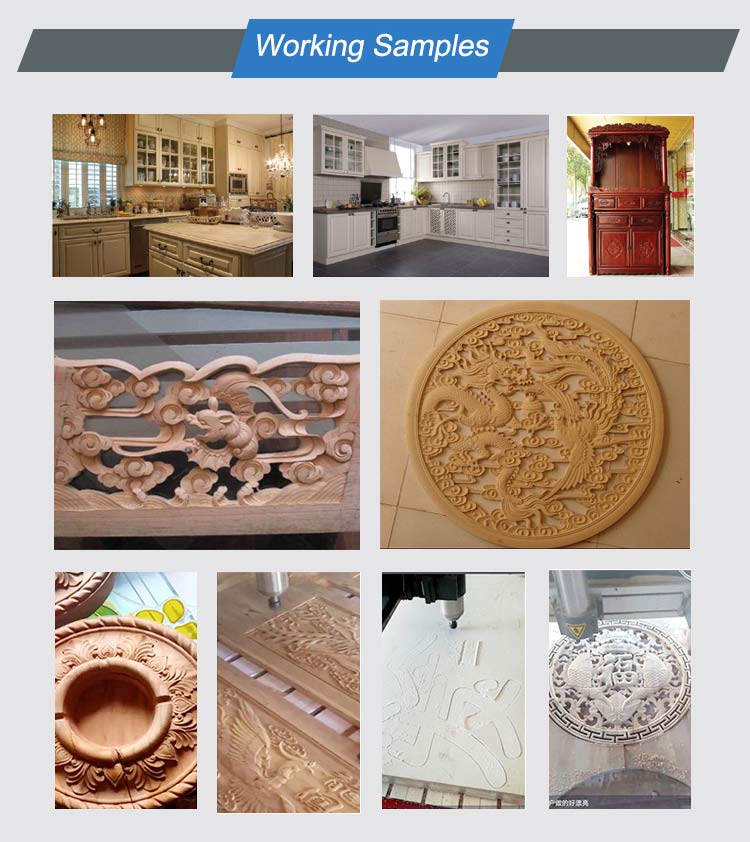

Working Samples:

FAQ:

Q1.How to get the most suitable machine and best price

Please tell the material you want to working on ?

How to working on it ? Engraving ? Cutting ? Or other ?

What’s the MAX size of these material ?( length ? Width ? Thickness ?)

Q2.What is the payment?

The payment is 30% or 50% T/T or Alibaba trade assurance in advance, balance after machine finished.

Q3.What is the producing time after order?

The proucing time is about 10-20 days depend on different machines.

Q4.If we don’t know how to use the machine,can you teach us?

Yes,we will ,if you come to China,we will offer you free training until you can use machine freely.And if

you are busy ,we will have the special engineer to your country,but you need to bear some fee,like

tickets and hotel and meal.

Q5.How about your after-sales service?

we offer you 24 hours service phone,skype or whatsapp, our engineer also can go to door install or training.

Q6. Quality Control:

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure they can work very well before being out of factory.

The testing video and pictures will be available before delivery.