With the process of industrialization, sheet metal is more and more commonly used in life, and sheet metal cutting is also increasingly concerned. Laser cutting machine is widely used for sheet metal cutting as an efficient and fast laser processing equipment, but it is usually used for precision cutting of thin plates. What should be used to cut 8mm carbon steel plates?

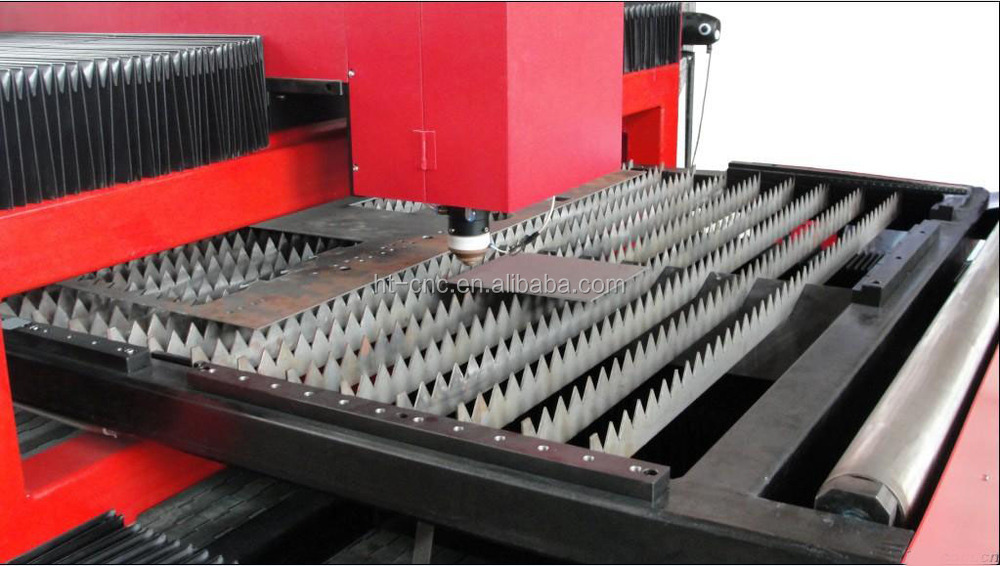

For 8mm carbon steel plate cutting, I suggest to use optical fiber laser cutting machine. The whole equipment is of work-piece fixed and gantry mobile structure. It is a CNC laser cutting machine with two axes linkage and three axes control. The X and Y axes linkage realizes plane cutting feed, and the Z axis floats to track the workpiece surface. Be able to track the sheet metal whose cutting surface is not very flat.

The thickness of stainless steel cut by laser fiber optic cutting machine is 4mm, and the thickness of carbon steel cut by laser fiber optic cutting machine is 8mm. There is no need to add auxiliary gas during processing, and the photoelectric conversion rate is high, which can greatly reduce the cost. Compared with CO2 laser cutting machine and YAG laser cutting machine, the optical fiber cutting machine has the following advantages:

1. The photoelectric conversion efficiency can reach 30%, twice that of CO2;

2. Low power consumption, 20%~30% of CO2;

3. No laser working gas, which can save a lot of laser maintenance costs;

4. Optical fiber transmission, no need for mirrors, no need to adjust the optical path.